Grundlegende Funktion eines Auto-Relais in Fahrzeugelektrik-Systemen

Auto-Relais funktionieren im Grunde wie elektrische Schalter, die den Stromfluss von kleinen Steuerkreisen zu größeren Stromversorgungssystemen ohne Probleme regeln. Den Antrieb dafür liefert eine innenliegende elektromagnetische Spule, die aktiviert wird, sobald ein 12-Volt-Gleichstromsignal ankommt. Sobald diese aktiviert ist, werden physische Metallkontakte bewegt, entweder um Stromkreise zu verbinden oder zu unterbrechen, die Ströme im Bereich von 30 bis 40 Ampere leiten können. Diese Art von Leistungsfähigkeit liegt weit über dem, was normale Schalter am Armaturenbrett jemals bewältigen könnten, weshalb Relais unverzichtbar sind, um höhere elektrische Lasten sicher zu steuern.

Wie Auto-Relais als elektromechanische Schalter in Fahrzeugstromkreisen funktionieren

Wenn jemand in seinem Auto einen Schalter betätigt, wie zum Beispiel die Scheinwerfer nachts einschaltet, passiert unter der Haube etwas ziemlich Interessantes. Die Aktion sendet ein 12-Volt-Signal an die Relaisspule, wodurch ein magnetisches Feld erzeugt wird, das stark genug ist, um den federbelasteten Teil im Inneren des Relais nach unten zu ziehen. Dieser gesamte Mechanismus funktioniert, weil dadurch der kleine Steuerkreis von dem Bereich getrennt bleibt, in dem die elektrische Arbeit mit hohem Stromfluss stattfindet. Stellen Sie es sich so vor: Der eigentliche Schalter, den der Fahrer berührt, muss kaum Strom führen – vielleicht etwa ein halber Ampere –, während das Relais selbst bis zu zwanzig Ampere direkt zu den Scheinwerfern leiten kann. Und diese Relais sind in der Regel auch in der Nähe der Batterie verdrahtet, sodass sie kürzere und dickere Leitungen mit höherem Querschnitt verwenden können, die den zusätzlichen Stromfluss ohne Überhitzung oder langfristige Schäden aushalten.

Die Rolle von Auto-Relais bei der Steuerung hochstrombetriebener Geräte über Niedrigstromkreise

Relais funktionieren im Grunde wie ferngesteuerte Schalter, die es ermöglichen, dass diese dünnen 18- bis 22-AWG-Leitungen im Fahrzeuginneren größere Verbraucher mit deutlich höherem Strombedarf steuern können. Ein aktueller Fahrzeugelektronik-Bericht aus 2024 stellte fest, dass solche Relaisanordnungen das Leitungsgewicht um etwa 17 Prozent gegenüber älteren direkt geschalteten Systemen reduzieren. Solche Einsparungen spielen besonders bei Verbrauchern eine Rolle, die viel elektrischen Strom benötigen – beispielsweise Kraftstoffpumpen mit einem Stromverbrauch von etwa 8 bis 10 Ampere oder Kühlerlüftern, die zwischen 15 und 25 Ampere ziehen. Eine solche Anordnung ist sowohl aus Sicht der Gewichtsreduktion als auch aus Gründen der Übersichtlichkeit und Belastbarkeit der elektrischen Systeme sinnvoll, um Schaltkreise nicht zu überlasten.

Warum 12-V-DC-Auto-Relais für eine effiziente Stromversorgung in Fahrzeugen unverzichtbar sind

Fahrzeuge, die mit standardmäßigen 12-Volt-Gleichstromsystemen betrieben werden, sind auf Relais angewiesen, um Spannungsverluste zu reduzieren, wenn der Strom über lange Kabelstrecken fließen muss. Durch die Platzierung des Hauptschalters in der Nähe der Batterie stellen diese Relais sicher, dass stromhungrige Komponenten die benötigte Energie erhalten, ohne Energie in den Steuerleitungen zu verschwenden. Auch die Sicherheit ist hier ein erwähnenswerter Vorteil. Wenn etwas schief läuft und irgendwo ein Kurzschluss entsteht, übernimmt die Sicherung ihre Aufgabe und schützt so den Rest des Systems, anstatt kleine Schalter so stark aufzuheizen, dass sie schmelzen oder Feuer fangen könnten. Wirklich cleveres Engineering.

Aufbau und Funktionsweise von Fahrzeugrelais

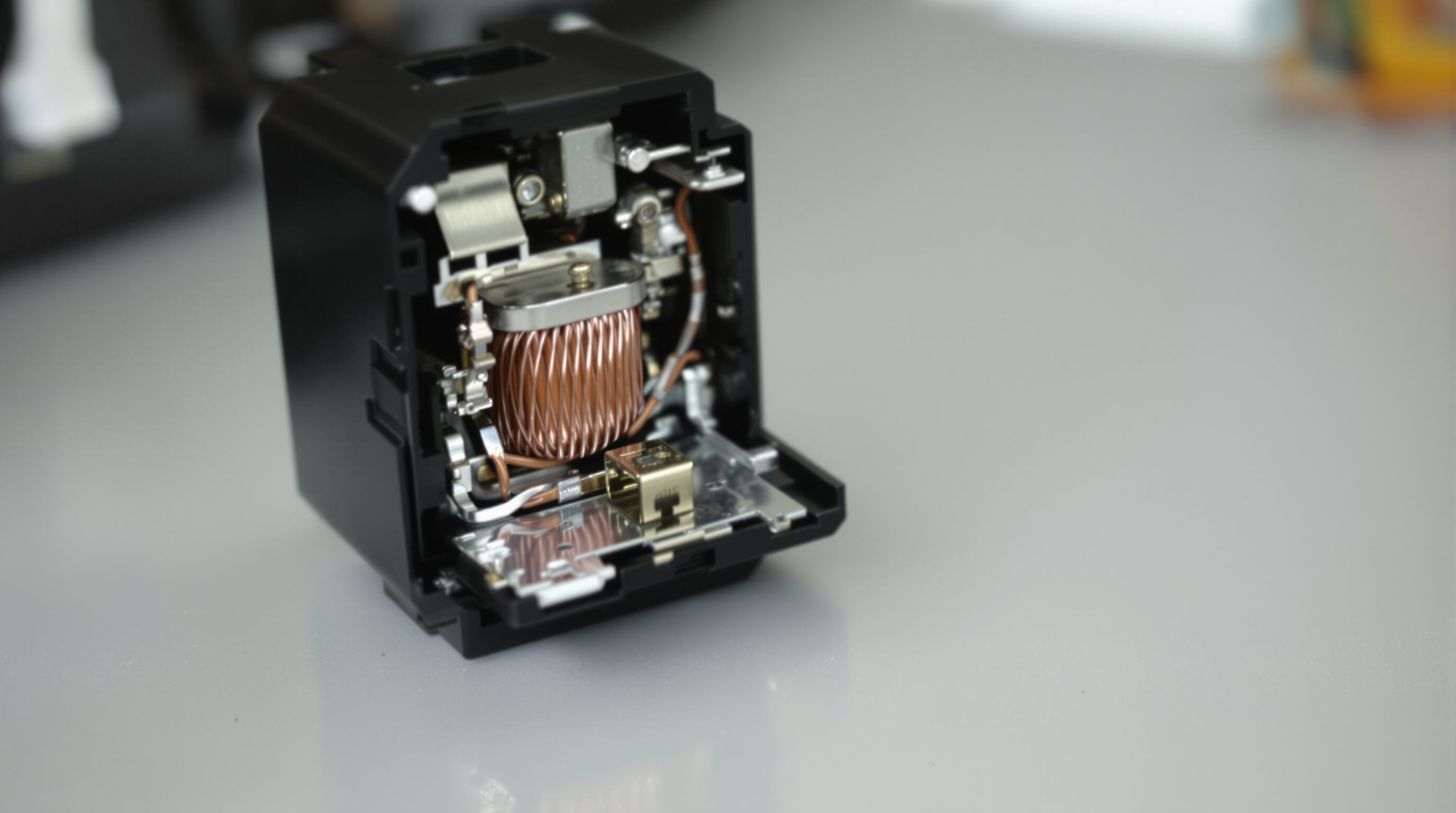

Hauptkomponenten: Spule, Kontakte, Anker und Relaisgehäuse

Ein Fahrzeugrelais integriert vier wesentliche Elemente:

- Elektromagnetische Spule : Erzeugt ein Magnetfeld, sobald Strom anliegt (typischerweise bei 12 V Gleichstrom)

- Anker : Bewegliche Eisenplatte, die durch das Magnetfeld der Spule angezogen wird

- Kontaktpersonen : Leiter, die den Hauptstromkreis öffnen oder schließen (Typen mit normalerweise geöffneten oder geschlossenen Kontakten)

- Gehäuse : Thermoplastgehäuse mit Schutz gegen Staub/Wasser und Schwingungsdämpfung

Standard-12V-Relais sind darauf ausgelegt, Lasten von bis zu 30A zu schalten und Motorenraum-Temperaturen von über 85°C standzuhalten. Mit einem Spuleneinschaltstrom von ca. 200mA ermöglichen sie kleine Steuersignale, um leistungsstarke Stromkreise zu steuern, ohne Armaturenbrett- oder Lenksäulen-Schalter zu belasten.

Wie Elektromagnetismus das Relaischalten in Automobilanwendungen ermöglicht

Wenn an die Spule eine Spannung angelegt wird, entsteht durch elektromagnetische Induktion ein Magnetfeld, das den Anker (Anker) zum Kern zieht. Die Bewegung dieses Teils schließt tatsächlich die Kontaktpunkte, sodass Strom durch den Hauptkreis fließen kann, der schwere Lasten bewältigt. Sobald das Steuersignal verschwindet, bricht das Magnetfeld zusammen und eine Feder drückt den Anker wieder in seine Ausgangsposition zurück, wodurch die elektrische Verbindung unterbrochen wird. Diese Sicherheitsfunktion verhindert gefährliches Rückstauen und sorgt dafür, dass die Komponente zuverlässig über 100.000 Schaltzyklen lang funktioniert. Eine solche Langlebigkeit macht diese Bauteile zu unverzichtbaren Elementen für wichtige Systeme wie Kraftstoffförderanlagen und industrielle Kühleinrichtungen, bei denen ein Ausfall keine Option ist.

Schrittweiser Aktivierungsprozess: Vom Signaleingang bis zur Stromkreisschließung

- Ein 12-V-Steuersignal erreicht die Relaisspule (Aktivierungsstrom: 30–70 mA)

- Die Spule erzeugt ein Magnetfeld (â‚2,5 mT in Standardmaßeinheiten)

- Der Anker schnappt in Kontakt mit dem Anschlusspunkt

- Der Hauptstromkreis schließt sich und ermöglicht einen Stromfluss von 10–40A zum Gerät

- Das Entfernen des Signals lässt das Feld zusammenbrechen; eine Feder setzt die Kontakte zurück

Diese Abfolge wird innerhalb von 8–15 Millisekunden abgeschlossen – schnell genug für schnelle Operationen wie Intervallschaltung der Scheibenwischer – und gewährleistet dabei gleichzeitig die vollständige elektrische Trennung zwischen Steuer- und Lastkreisen.

Hauptanwendungen von Auto-Relais bei der Versorgung kritischer Fahrzeugsysteme

Steuerung von Hochleistungskomponenten wie Kraftstoffpumpen, Anlassermotoren und Kühllüftern

Auto-Relais funktionieren als Verkehrskontroller für Hochstromsysteme und steuern Lasten von 20–50A für Kraftstoffpumpen, Anlassermotoren (die während des Starts 75–150A ziehen können) und Kühllüfter am Kühler. Durch die Fernsteuerung dieser Ströme ermöglichen Relais, dass im Fahrzeuginneren dünne Leitungen mit einem Querschnitt von 18–22 AWG die leistungsstarken Verbraucher aktivieren können, ohne zu überhitzen oder Brandgefahr zu erzeugen.

Verwendung von Auto-Relais zum Schutz von Schaltern und zur Reduzierung der elektrischen Belastung auf Steuerkreise

Das Relaisystem schützt empfindliche Steuerschalter vor hohen Strombelastungen. In einem typischen Scheinwerferstromkreis reduzieren Relais die Schaltbelastung von 10–15A auf unter 0,5A und verlängern so die Lebensdauer der Schalter um 400–600%. Diese Trennung verhindert zudem Spannungsabfälle, die die Funktion empfindlicher Elektronik wie Steuergeräte (ECUs) und Infotainmentsysteme stören könnten.

Relais-Treiberschaltungen und ihre Bedeutung für zuverlässige Hochstrom-Anwendungen

Moderne Fahrerschaltungen sind mit verschiedenen Schutzmaßnahmen ausgestattet, wie z.B. Freilaufdioden, die dabei helfen, die unangenehmen Spannungsspitzen zu regulieren, die entstehen, wenn magnetische Felder plötzlich zusammenbrechen. Solche Verbesserungen machen in Systemen, bei denen Zuverlässigkeit entscheidend ist, einen großen Unterschied. Kraftstoffpumpenrelais verfügen beispielsweise häufig über eingebaute Crash-Sensoren, die im Unfallfall automatisch die Systeme abschalten. Starterrelais funktionieren zwar anders, erfüllen jedoch einen ähnlichen Zweck, indem sie verhindern, dass der Motor startet, wenn die Gänge nicht ordnungsgemäß eingelegt sind, um Schäden durch Quietschgeräusche zu vermeiden. In besonders ausgeklügelten Anlagen werden sogar mehrere parallele Relais als Backup-Systeme eingesetzt, insbesondere für kritische Komponenten wie Bremsaktuatoren, bei denen ein Versagen keine Option ist.

Auto-Relais in der Motorsteuerung und bei automotiven Komfortfunktionen

Ansteuerung von Gleichstrommotoren mit Bürsten in Fensterhebern, Schiebedächern und Scheibenwischern

In Komfortsystemen fungieren Relais als Zwischenstation für Gleichstrommotoren mit Bürsten. Laut Daten des Automotive Engineering Institute vom letzten Jahr können Armaturentafelschalter, die für etwa 2 bis 5 Ampere ausgelegt sind, tatsächlich deutlich höhere Motorlasten zwischen 15 und 30 Ampere bewältigen. Möglich wird dies dadurch, dass Relais die Steuerleitungen von den stromstarken Leitungen trennen. Diese Trennung verhindert gefährliches Lichtbogenentstehen und sorgt dafür, dass Komponenten länger halten – ein entscheidender Faktor bei Systemen, die mehrfach täglich ein- und ausgeschaltet werden.

Wie Auto-Relais die Langlebigkeit in Hochzyklus-Motoranwendungen verbessern

In Hochzyklus-Anwendungen wie Schiebedachmotoren (50.000+ Aktivierungen) reduzieren Relais die elektrische Belastung um 83 % im Vergleich zu direktem Schaltungstechnik (Vehicle Systems Journal 2023). Da das Relais die physische Kontaktschaltung übernimmt, vermeidet der Steuerschalter Erosion und Abnutzung. Diese Langlebigkeit ist besonders wichtig für Systeme, die eine sofortige Polaritätsumkehr benötigen, wie z. B. automatische Fenstersteuerungen.

Relais Einsatz in Scheinwerfern, Hupe, Nebelscheinwerfern und Fernlichtsteuerkreise

Beleuchtungs- und Signalanlagen würden ohne Relais, die diese hohen Ströme schalten, nicht ordnungsgemäß funktionieren, typischerweise etwa 30 bis 40 Ampere für Komponenten wie Scheinwerfer, Nebelscheinwerfer und Hupe, wobei verhindert wird, dass normale Schalter überlastet werden. Bei Fernlichtkreisen sorgen Relais für eine sicherere Schaltoperation zwischen verschiedenen Lichtstellungen, wodurch jene lästigen Entladungen beim Lichtwechsel in der Nacht reduziert werden. Die meisten Ingenieure bevorzugen Relaislösungen, da diese unter solchen Beanspruchungen einfach länger halten. Ein Beispiel hierfür sind Scheinwerferrelais, die oft mehr als 10.000 Schaltzyklen verkraften, bevor erste Verschleißerscheinungen auftreten, wodurch sie zu äußerst zuverlässigen Komponenten in Fahrzeugelektriksystemen werden, trotz der ständigen Ein- und Ausschaltvorgänge.

Arten von Fahrzeugrelais: Elektromechanische Relais, Halbleiterrelais und Zeitverzögerungsrelais

Drei Haupttypen von Relais werden in modernen Fahrzeugen verwendet:

| TYP | Schaltmechanismus | Hauptvorteile | Häufige Anwendungsfälle |

|---|---|---|---|

| ELEKTROMECHANISCH | Physikalische Kontakte & Spule | Kosteneffizient, leicht auszutauschen | Scheinwerfer, Hupe |

| Festkörper | Halbleiterkomponenten | Leise, keine beweglichen Teile | LED-Beleuchtung, EV-Systeme |

| Zeitverzögerung | Programmierbare Schaltungstechnik | Sequenzielle Aktivierung | Innenbeleuchtung, Alarmanlagen |

Branchendaten zeigen, dass Halbleiterrelais mittlerweile 32 % der neuen Fahrzeuganwendungen ausmachen (Automotive Electrical Systems Report 2024), insbesondere in Hybridfahrzeugen und Elektrofahrzeugen, bei denen leiser Betrieb den Komfort verbessert.

Anwendungen von Zeitverzögerungsrelais und Halbleiterrelais in Innenbeleuchtung und Sicherheitssystemen

Die Zeitverzögerungsrelais verfügen über praktische Funktionen, wie zum Beispiel das langsame Verlöschen der Innenbeleuchtung nach dem Schließen der Türen, was die Batterielebensdauer verlängert und für die Passagiere mehr Komfort schafft. Bei Sicherheitssystemen kommen Halbleiterrelais zum Einsatz, die nahezu augenblicklich auf Einbruchversuche reagieren, üblicherweise innerhalb von etwa 0,1 Millisekunden. Diese Bauteile arbeiten zudem mit CAN-Bus-Netzwerken zusammen und verbrauchen, wenn sie nicht aktiv genutzt werden, weniger als 0,5 Watt. Dies trägt dazu bei, moderne Sicherheitssysteme hinsichtlich des Energieverbrauchs in verschiedenen Fahrzeuganwendungen deutlich effizienter zu gestalten.

FAQ

Welche Hauptfunktion hat ein Fahrzeugrelais in einem Auto?

Ein Fahrzeugrelais fungiert hauptsächlich als elektrischer Schalter, der den Stromfluss von kleineren Steuerkreisen zu größeren Stromsystemen regelt und dadurch die Steuerung von Hochstromverbrauchern durch Niedrigstromkreise ermöglicht.

Warum sind 24 V Gleichstrom-Auto-Relais wichtig für das Fahrzeugstrommanagement?

24 V Gleichstrom-Auto-Relais sind wichtig, da sie Spannungsverluste über lange Kabel reduzieren, eine effiziente Stromversorgung energieintensiver Komponenten sicherstellen und Steuerschalter vor Überhitzung und potenziellen Brandgefahren schützen.

Wie verbessern Auto-Relais die Langlebigkeit von Fahrzeugsystemen?

Auto-Relais verlängern die Lebensdauer von Steuerschaltern, indem sie deren elektrische Belastung verringern, Verschleiß durch direkten elektrischen Kontakt verhindern und Steuerung von stromstarken Stromkreisen trennen, wodurch Systeme effizient weiterlaufen.

Welche verschiedenen Arten von Auto-Relais und deren Anwendungen gibt es?

Es gibt drei Haupttypen von Automotive-Relais: Elektromechanische Relais, die physische Kontakte und Spulen für allgemeine Anwendungen wie Scheinwerfer verwenden; Halbleiterrelais, die aus Halbleiterbauelementen bestehen und in Systemen eingesetzt werden, bei denen stilles Betreiben erforderlich ist, wie z. B. bei Elektrofahrzeugen (EVs); und Zeitverzögerungsrelais, die für sequenzielle Aktivierung in Innenbeleuchtung und Alarmsystemen verwendet werden.

Inhaltsverzeichnis

- Grundlegende Funktion eines Auto-Relais in Fahrzeugelektrik-Systemen

- Aufbau und Funktionsweise von Fahrzeugrelais

- Hauptanwendungen von Auto-Relais bei der Versorgung kritischer Fahrzeugsysteme

- Auto-Relais in der Motorsteuerung und bei automotiven Komfortfunktionen

- Relais Einsatz in Scheinwerfern, Hupe, Nebelscheinwerfern und Fernlichtsteuerkreise

- Arten von Fahrzeugrelais: Elektromechanische Relais, Halbleiterrelais und Zeitverzögerungsrelais

- Anwendungen von Zeitverzögerungsrelais und Halbleiterrelais in Innenbeleuchtung und Sicherheitssystemen

- FAQ