امیدوارم که زمان خرید خوبی داشته باشید.

- بررسی اجمالی

- محصولات پیشنهادی

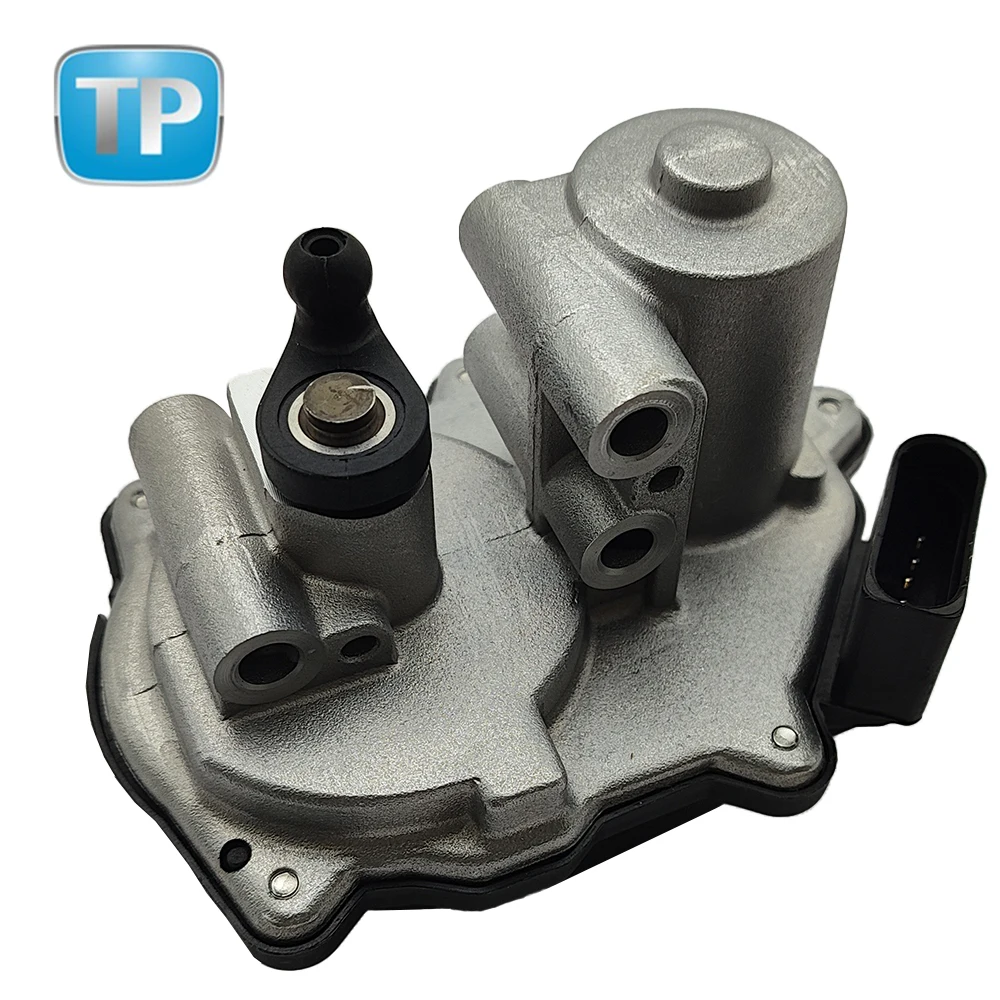

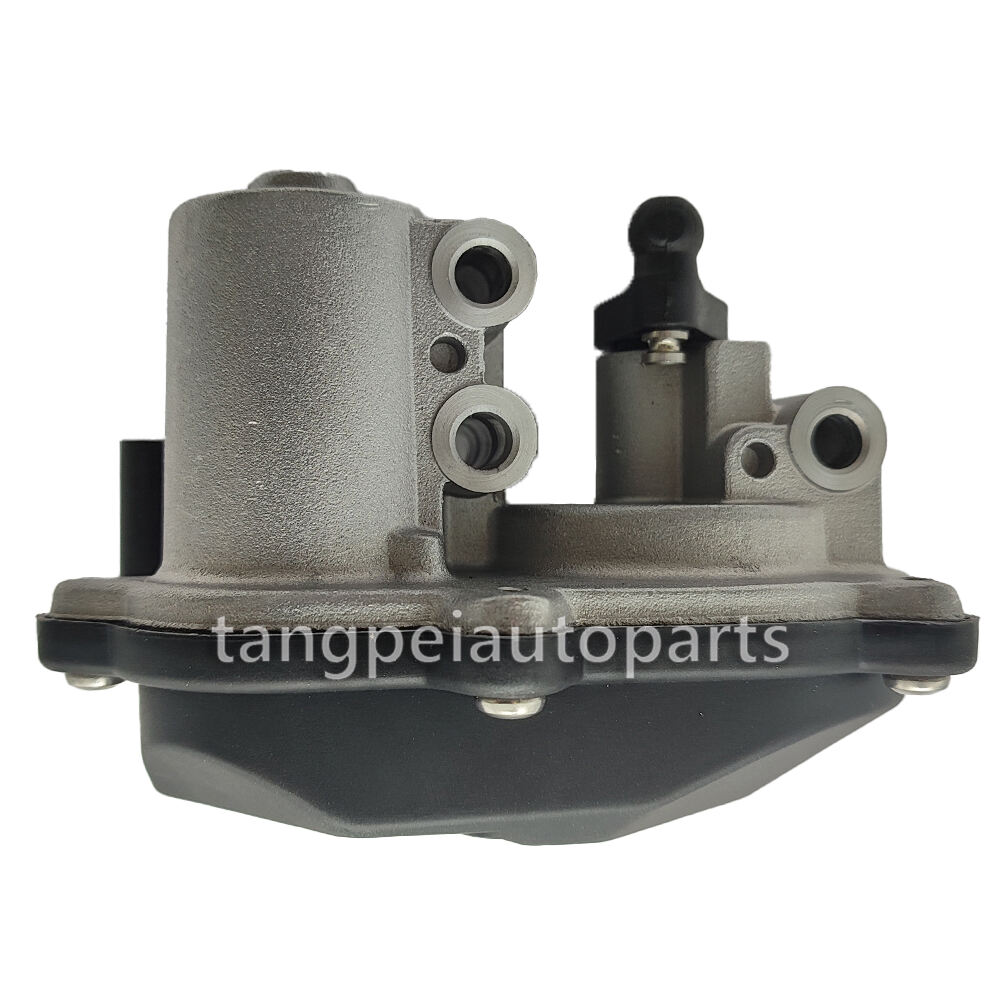

قطعات خودرو با کیفیت بالا فعالساز شیر منیفولد ورودی هوا برای اودی OEM 03L129086

۱۲ ماه گارانتی

مشخصات

مورد |

ارزش |

نه |

03L129086 |

وضعیت |

جدید |

مکان اصلی |

چین |

گوانگدونگ |

|

هدف |

برای تولید |

نام برند |

TangPei |

ضمانت |

12 ماه |

شماره مدل |

03L129086 |

نوع |

اجزاء جایگزین |

ساخت خودرو |

خودکار |

اندازه |

اندازه استاندارد |

3

اگر سوالی دارید، لطفاً بدون هیچ محدودیتی با من تماس بگیرید.

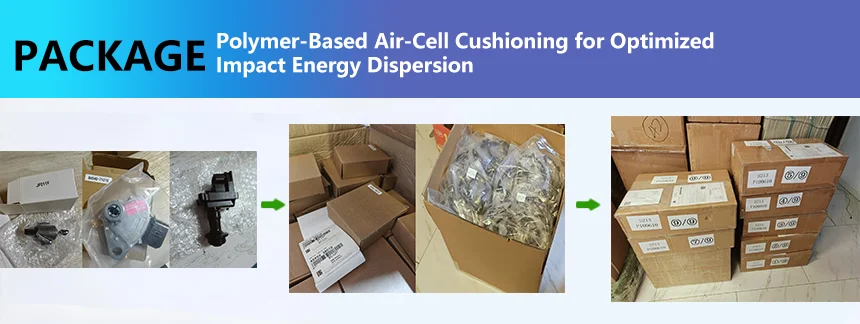

بستهبندی و ارسال

برای بهتر تضمین کردن ایمنی کالاهای شما، خدمات بسته بندی حرفهای، دوستدار محیط زیست، راحت و کارآمد ارائه خواهد شد.

شرایط پرداخت

مشخصات شرکت

شرکت گوانگژو تانگ پئی تریدینگ محدود، متخصص در قطعات خودرو است و بیش از ۲۰ سال در این حوزه فعالیت کرده است. محصولات عمده فروش ما شامل انواع سوزاکها، پمپ بنزین، مدار الکتریکی اشتعال، متر جریان هوا، حسگرهای اکسیژن، حسگر موقعیت دومبست، حسگر موقعیت کمربند، حسگر موقعیت دودک، حسگر فشار هوا، حسگر فشار روغن، حسگر پارکینگ، حسگر سرعت، مخابره اشتعال، ماژول اشتعال، ولواج کنترل سرعت، علامتگذاری روغن، گasket و غیره میباشد. بیشتر این محصولات اقلام اصیلی هستند که در ژاپن تولید شدهاند، ما همچنین دارای محصولات دیگری هستیم که در چین یا تایوان تولید میشوند، بنابراین میتوانید از ما به انتخاب خود محصولات با کیفیت مختلفی را تهیه کنید، به درخواست مشتریان وابسته است. ما شهرت خوبی برای محصولات با کیفیت ثابت داریم و توسط مشتریان داخلی و خارجی خوب پذیرفته شدهایم. "رضایت شما بزرگترین پاداش ما است" و "مشتری اول، کیفیت اول، خدمات اول" اصل ماست. ما به صورت صمیمانه امیدواریم با مشتریانی از سراسر جهان همکاری کنیم، اگر مایلید اطلاعات بیشتری داشته باشید، لطفاً با ما تماس بگیرید، ما به ایجاد یک رابطه تجاری عالی با شما انتظار داریم.

سوالات متداول

1. ما کی هستیم؟

ما در استان گوانگدونگ، چین قرار داریم و از سال ۲۰۱۶ فعالیت میکنیم. بازار ما شامل آمریکای جنوبی (۲۵٫۰۰٪)، آمریکای شمالی (۲۰٫۰۰٪)، جنوب شرق آسیا (۲۰٫۰۰٪)، اروپای غربی (۱۰٫۰۰٪)، اروپای شمالی (۱۰٫۰۰٪)، اروپای جنوبی (۵٫۰۰٪)، آفریقا (۵٫۰۰٪) و اروپای شرقی (۵٫۰۰٪) است. تعداد کل کارکنان اداره ما حدود ۵ تا ۱۰ نفر است.

2. چگونه میتوانیم کیفیت را تضمین کنیم؟

همیشه یک نمونه پیش تولید قبل از تولید انبوه؛

همیشه بازرسی نهایی قبل از حمل و نقل؛

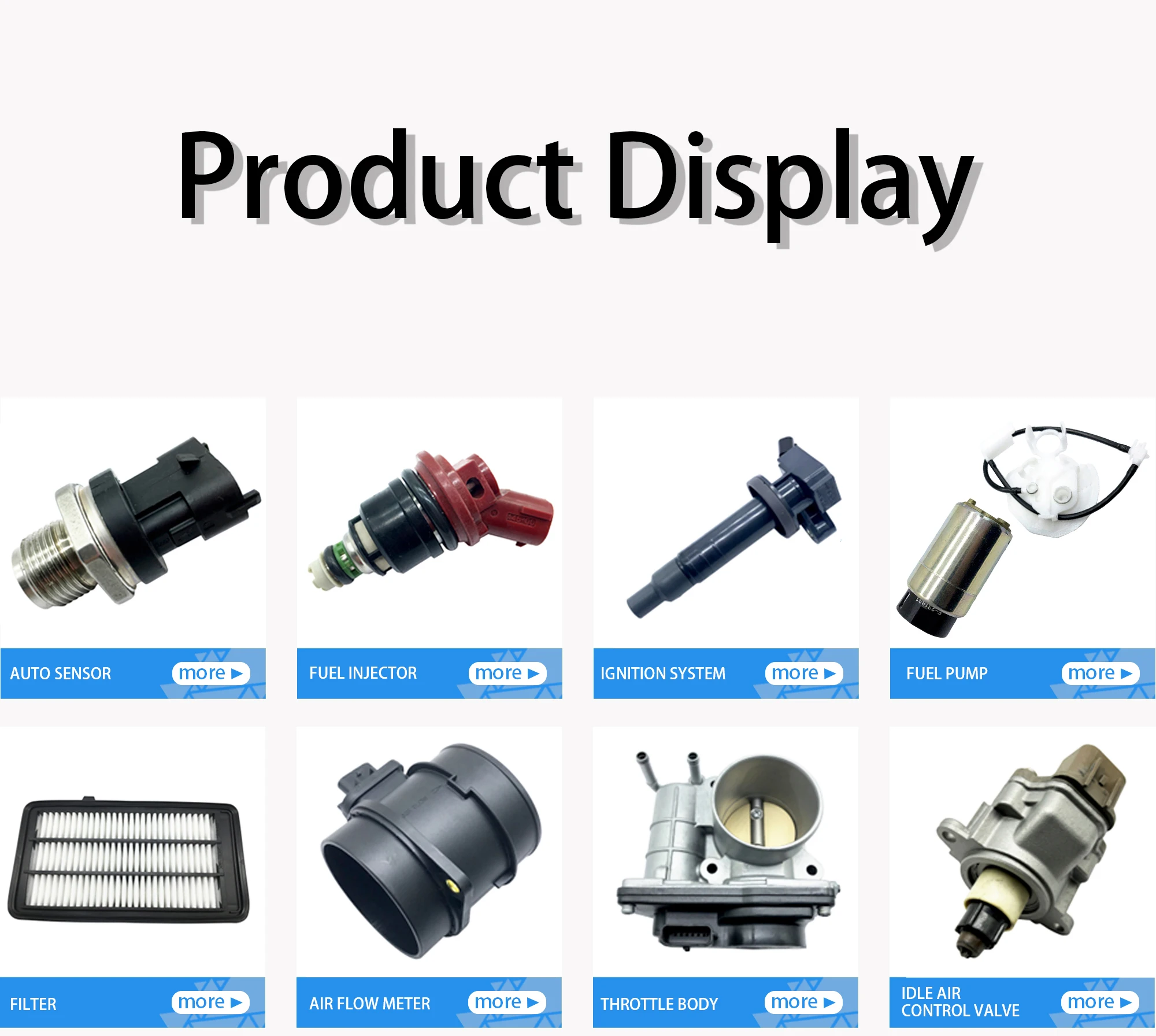

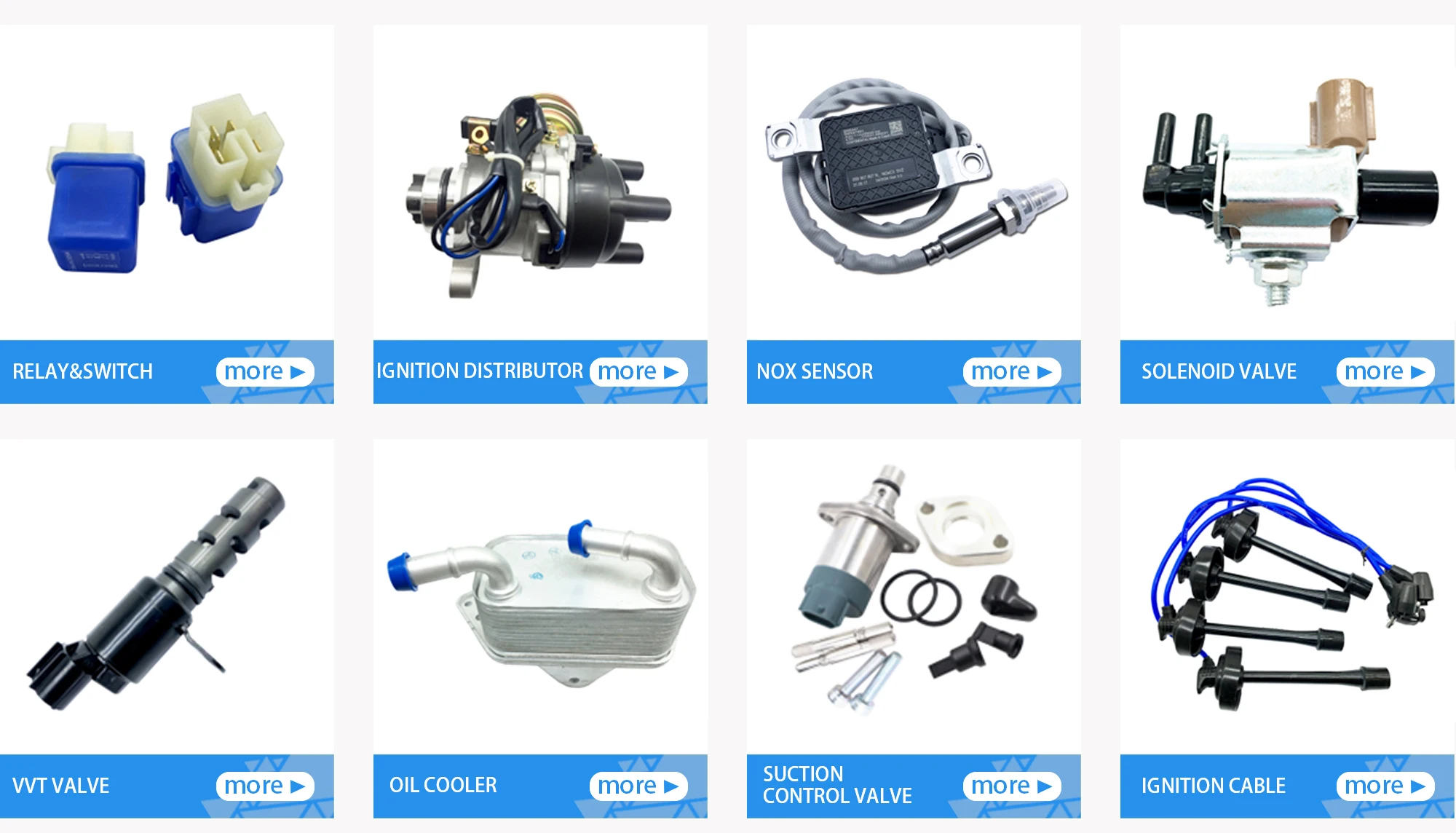

3. چه چیزی میتوانید از ما خریداری کنید؟

حسگر، انژکتور، ولواج کنترل، سلف اشتعال، میترباد هوا

4. چرا باید از ما خرید کنید نه از تأمینکنندگان دیگر؟

شرکت گوانگژو تانگ پئی تریدینگ به طور حرفهای در زمینه قطعات خودرو فعالیت میکند و بیش از ۱۰ سال سابقه دارد. محصولات عمده فروشی ما شامل انواع قطعات الکترونیکی برای خودروهاست. ما به خاطر کیفیت ثابت محصولات خود شهرت داریم، ممنون!

5. چه خدماتی میتوانیم ارائه دهیم؟

شرایط تحویل قابل پذیرش: FOB، EXW؛

ارز قابل پذیرش برای پرداخت: دلار آمریکا، یورو، دلار استرالیا، دلار هنگ کong، یوان چین؛

نوع پرداخت قابل قبول: T/T، MoneyGram، PayPal، Western Union، نقدی، Escrow;

زبانهای صحبت شده: انگلیسی، چینی

ما در استان گوانگدونگ، چین قرار داریم و از سال ۲۰۱۶ فعالیت میکنیم. بازار ما شامل آمریکای جنوبی (۲۵٫۰۰٪)، آمریکای شمالی (۲۰٫۰۰٪)، جنوب شرق آسیا (۲۰٫۰۰٪)، اروپای غربی (۱۰٫۰۰٪)، اروپای شمالی (۱۰٫۰۰٪)، اروپای جنوبی (۵٫۰۰٪)، آفریقا (۵٫۰۰٪) و اروپای شرقی (۵٫۰۰٪) است. تعداد کل کارکنان اداره ما حدود ۵ تا ۱۰ نفر است.

2. چگونه میتوانیم کیفیت را تضمین کنیم؟

همیشه یک نمونه پیش تولید قبل از تولید انبوه؛

همیشه بازرسی نهایی قبل از حمل و نقل؛

3. چه چیزی میتوانید از ما خریداری کنید؟

حسگر، انژکتور، ولواج کنترل، سلف اشتعال، میترباد هوا

4. چرا باید از ما خرید کنید نه از تأمینکنندگان دیگر؟

شرکت گوانگژو تانگ پئی تریدینگ به طور حرفهای در زمینه قطعات خودرو فعالیت میکند و بیش از ۱۰ سال سابقه دارد. محصولات عمده فروشی ما شامل انواع قطعات الکترونیکی برای خودروهاست. ما به خاطر کیفیت ثابت محصولات خود شهرت داریم، ممنون!

5. چه خدماتی میتوانیم ارائه دهیم؟

شرایط تحویل قابل پذیرش: FOB، EXW؛

ارز قابل پذیرش برای پرداخت: دلار آمریکا، یورو، دلار استرالیا، دلار هنگ کong، یوان چین؛

نوع پرداخت قابل قبول: T/T، MoneyGram، PayPal، Western Union، نقدی، Escrow;

زبانهای صحبت شده: انگلیسی، چینی